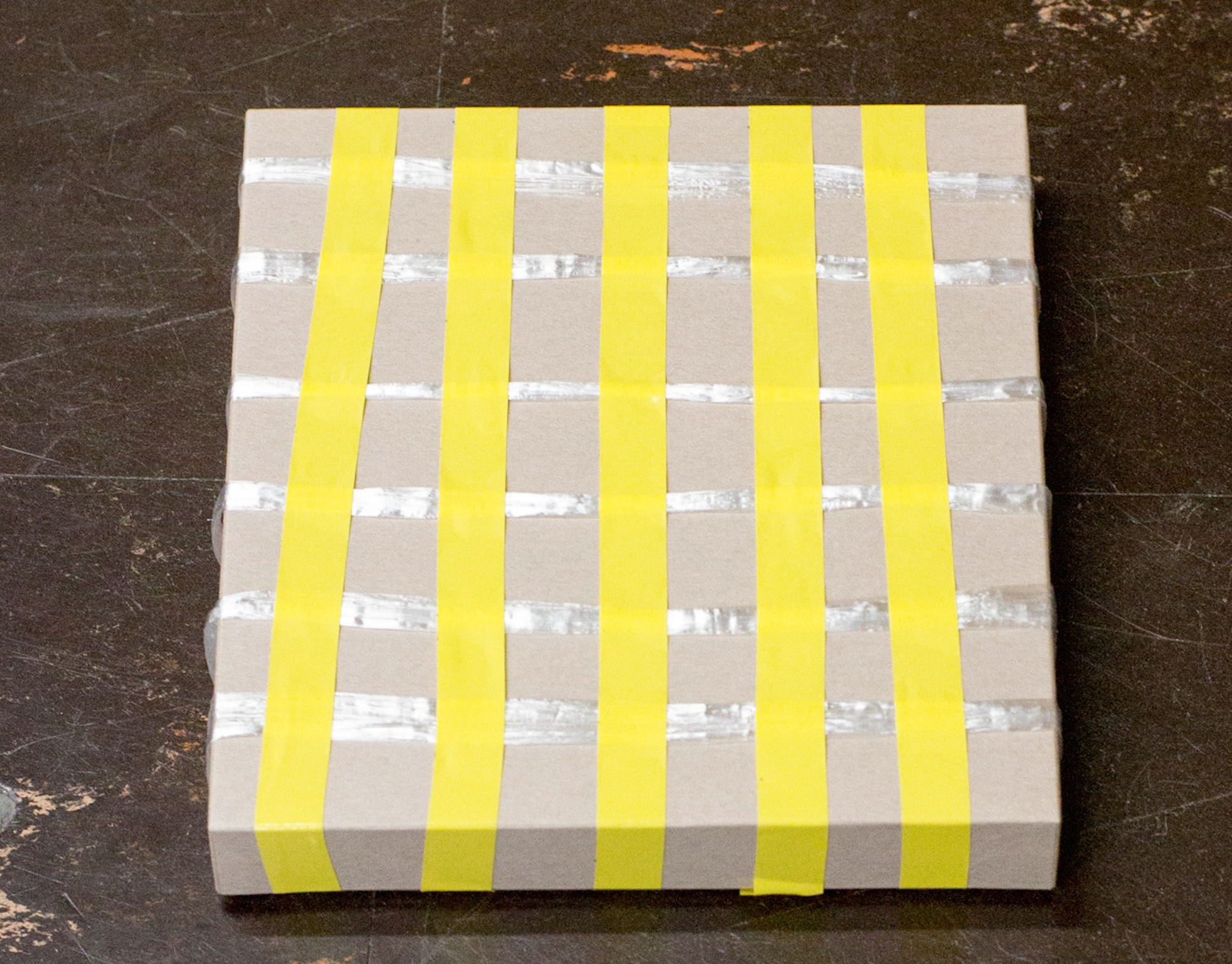

デンマークのオーフス建築大学で行ったロボットアームファブリケーションのワークショップ。

ロボットアームのツールヘッドと動きをデザインし、その痕跡を粘土に残す。

-

drawing : Taichi Sunayama

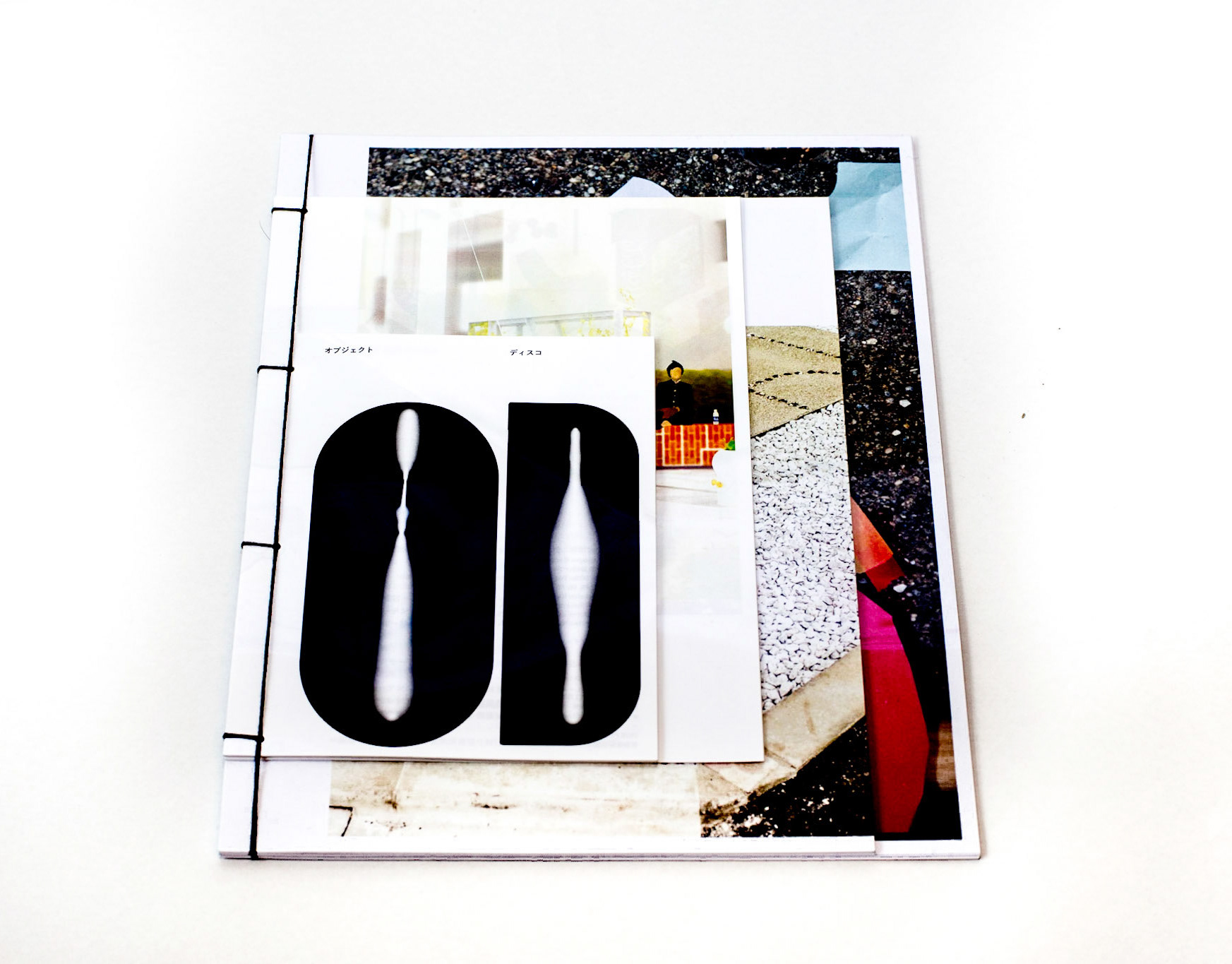

A- obverse / A- reverse

HARD CO(U)R(S)E 2015

HARD CO(U)R(S)E 2015

project team : Toshikatsu Kiuchi, Taichi Sunayama, Dana Maier & Maya Lahmy

---

[ Workshop Document]

A- obverse / A- reverse is a two weeks workshop where robotic fabrication is introduced and discussed as a form generative process in architecture. The workshop title, “a-obverse / a-reverse”, is a coined word, meant to indicate a state of surface in a precise sense, which is not obverse neither reverse of an object but is the very surface of an object itself with no thickness. With this as starting point, we will investigate opportunities for active involvement of digital technologies in an architectural design development.

A concrete target of the workshop is materialization of “a-obverse / a-reverse” surface as s omething suspended in-between digital and physical output .

the process is as following;

A concrete target of the workshop is materialization of “a-obverse / a-reverse” surface as s omething suspended in-between digital and physical output .

the process is as following;

-

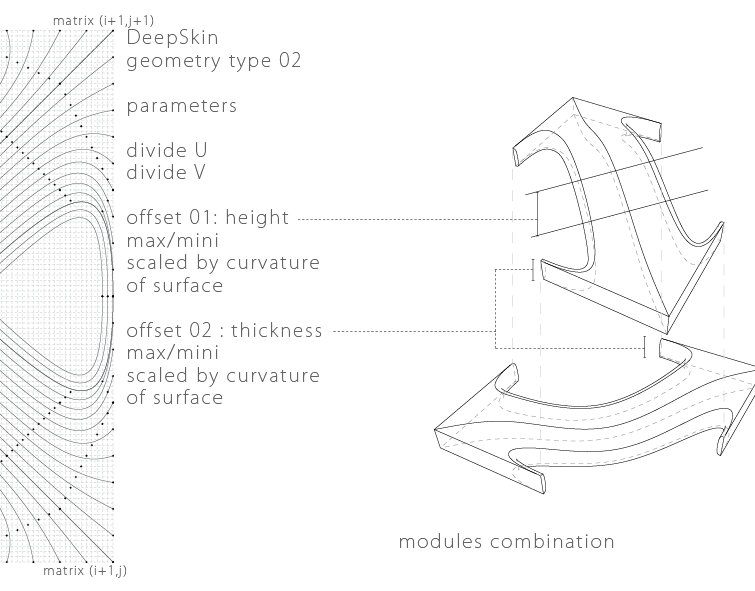

[1] Produce a custom tool head, in 3D modeler, by merging scanned object and joint piece to allow the object to be attached to the robotic arm .

[2] 3d print the tool head.

[3] Study how your custom tool should contact to clay; carve, scrape, drill, roughen, grind, push, pinch, deform… then, to realize the desired effects, digitally draw paths around clay for robotic arm to move your custom tool head along .

[4] run robot to shape clay, observe the result and repeat the same procedure with differentiated

parameters as multiple times as possible to obtain heterogeneous

parameters as multiple times as possible to obtain heterogeneous

-

HARDWARE | SOFTWARE | MATERIAL

· FARO edge scan arm with laser line probe HD | cam2measure

· IRB-120 industrial mini robot programmed through Rhino 5 | Grasshopper | HAL

· clay

· FARO edge scan arm with laser line probe HD | cam2measure

· IRB-120 industrial mini robot programmed through Rhino 5 | Grasshopper | HAL

· clay

---

-

photos : Taichi Sunayama (unless otherwise indicated)

-